Industries We Serve and Support

20+

Years Of Experience

Turnkey Extrusion Blow Molding Solutions

Efficient Extrusion Blow Molding Machines for Plastic Industry

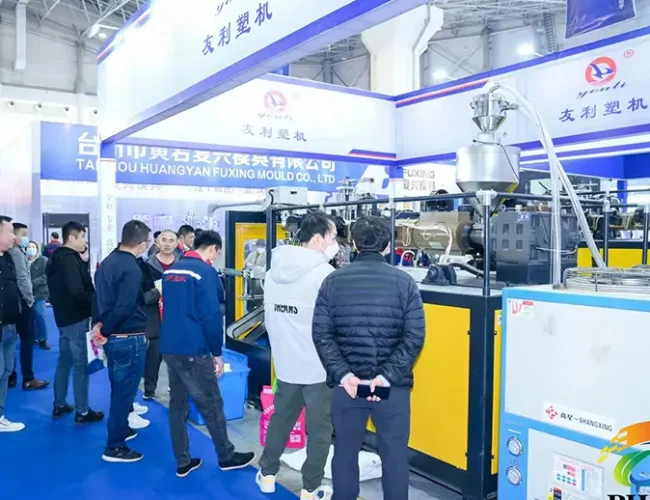

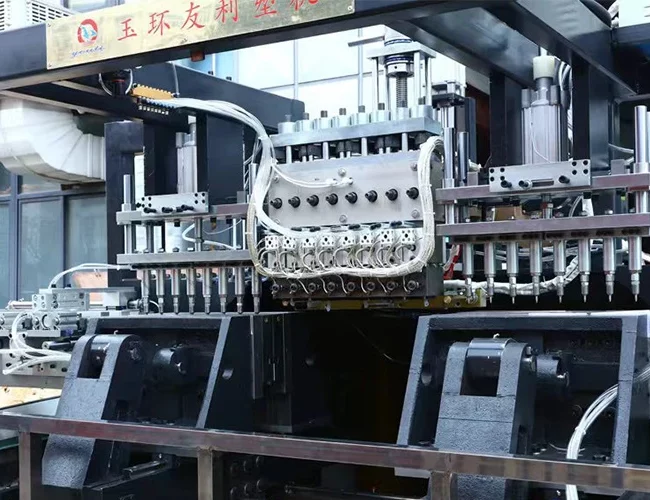

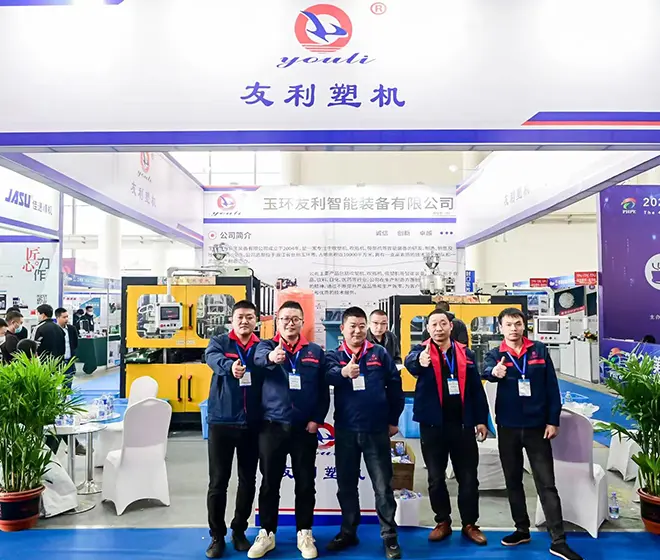

YOULI Machine is located in Yuhuan, Taizhou, Zhejiang Province, with a production area of nearly 10,000 square meters. We specialize in the design and manufacturing of extrusion blow molding machines, offering both fully electric and hydraulic models to meet diverse customer needs.

Our machines are capable of producing hollow plastic containers ranging from 0.5ml to 50L+, widely used across industries such as food & beverage, Daily Chemicals, Pharmaceutical & Agrochemical, Automotive Industry, and more.

With strong engineering capabilities and deep industry experience, YOULI provides complete turnkey solutions – from machine and mold design to auxiliary equipment and on-site commissioning – helping customers build efficient and reliable production lines.

Our products have been exported to more than 50 countries and regions, earning the trust of global clients through stable quality, customized service, and long-term technical support.

We're online – contact us now

Need a Reliable Factory?

MORE ABOUT YOULI COMPANY

Why Choose YOULI Blow Molding Machines

Strong R&D Capabilities

High Efficiency & Energy Saving

Providing Turnkey Solutions

Excellent After-Sales Support

MORE ABOUT YOULI COMPANY

Providing Turnkey Extrusion Blow Molding Solutions

Machine Selection & Configuration

We help you choose the right blow molding machine based on your product type, production volume, and material requirements.

Mold Design & Manufacturing

Our team provides customized mold solutions — from 2D/3D design to precise mold fabrication — ensuring optimal product quality and efficiency.

Auxiliary Equipment Integration

We supply and integrate supporting systems such as chillers, air compressors, mold temperature controllers, and conveyors for a complete line.

Installation, Commissioning & Training

Our engineers handle on-site installation, machine calibration, and hands-on training to ensure your production starts smoothly and safely.

MORE ABOUT YOULI COMPANY

Talk to Our Experts – Start Your Project Without Delay.

Our Testimonials

Feedback From Our Clients

MORE ABOUT YOULI COMPANY

Read Our Latest Articles

Send us a Message

If you have any questions or need assistance, feel free to leave us a message. We respect and protect your privacy.

Most Popular Questions

1. What types of blow molding machines do you manufacture?

As a professional top blow molding machine manufacturer, we offer a full range of extrusion blow molding machines, including all electric blow moulding machines, Servo Hydraulic models. Our equipment supports container volumes from 0.5ml to 50L+, ideal for diverse hollow plastic packaging applications.

2. Can your extrusion blow molding machines process different plastic materials?

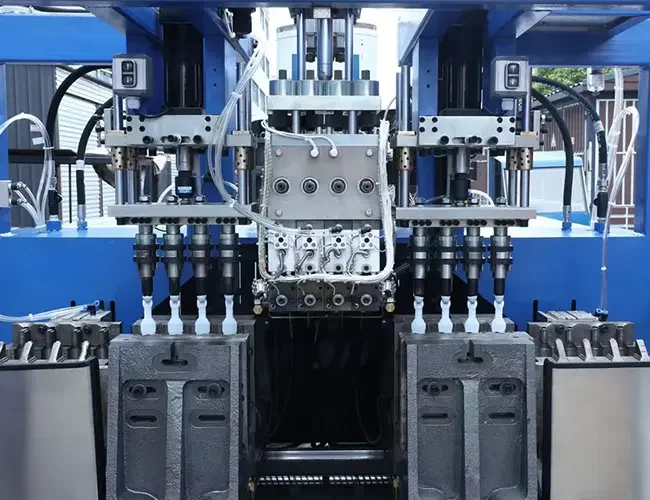

Yes. Our blow molding machine are designed to support a wide range of plastic resins as part of the extrusion blow molding process. Materials such as HDPE, LDPE, PP, PVC, PETG, and more can be processed efficiently. We provide customized screw and die head configurations to ensure optimal performance based on specific material characteristics.

3. Do you offer turnkey blow molding solutions?

Absolutely. We provide turnkey solutions that include blow molding machines, mold design, auxiliary equipment, automation, and system integration. Whether you need a standalone extrusion blow molding machine or a complete production line, we deliver end-to-end support.

4. Can you customize the blow molding machine based on our product design?

Yes, customization is our strength. As an experienced blow molding machine manufacturer, we can tailor the machine configuration, mold size, parison control, and automation level to meet your exact requirements, whether for milk bottles, jerry cans, pesticide bottles, chemical drums, or medical containers.

5. What is the lead time for your blow molding machines?

For most standard blow molding machines, the lead time is approximately 45 working days. If the order involves a turnkey solution, the delivery time may extend to around 60 working days. The exact lead time can vary depending on the machine type and order volume, so please consult our sales team for a confirmed schedule.

6. How many layers can a co-extrusion blow molding machine produce?

Depending on the machine configuration, it can produce 2 to 6 layers. Youli offers flexible multi-layer solutions tailored to specific application needs. Get a Free Quote Today

7. Do you provide overseas installation and training?

Yes. We offer global on-site installation and training services, including full commissioning of your blow molding machine. Remote technical support, multilingual manuals, and video guidance are also available to help you get started quickly.

8. What kind of after-sales service do you offer?

We offer 24/7 technical support, spare parts supply, and international engineer dispatch. With our smart PLC systems, we can provide remote diagnostics and machine monitoring, especially for high-end all electric blow moulding machines.

9. How do you handle packaging and shipping of the blow molding machines?

Each blow molding machine is securely packed in export-standard wooden crates, treated for rust protection. We provide full documentation including packing list, certificate of origin, bill of lading, and more, ensuring smooth delivery to over 50 countries.

10. What is your blow molding machine price and how is it determined?

Our blow molding machine price varies based on model type (e.g., all electric blow moulding machine vs. hydraulic), production capacity, and level of customization. Contact us directly for a detailed quotation—we always aim to offer cost-effective, value-driven solutions.