20+

Years Of Experience

Pesticide Bottle Blow Molding Machine Manufacturer

Youli provides high-performance pesticide bottle blow moulding machine designed for the safe, efficient, and scalable production of chemical packaging used in agriculture. Our machines are capable of producing agrochemical bottles, herbicide containers, insecticide jugs, and fertilizer bottles, with capacities ranging from 100ml to 25L or more.

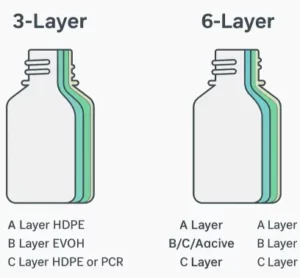

Each pesticide bottle blow molding machine is built to handle HDPE, PP, and other chemical-resistant plastics, ensuring durability and compatibility with corrosive or flammable liquids. Our systems support features like multi-layer co-extrusion, handle integration, and precise wall thickness control to meet regulatory and market demands.

Whether you need stackable pesticide bottles, trigger-spray compatible containers, or custom-molded jugs, Youli offers flexible mold customization and complete line integration. We also provide automation options such as deflashing units, leak testers, and labeling systems.

With exports to over 50 countries, Youli is a trusted pesticide bottle blow molding machine manufacturer offering reliable equipment and global technical support.

Contact us today to get a tailored solution and the best pesticide bottle blow molding machine price for your production needs.

Agrochemical Pesticide Bottle Blow Molding Machine

Share your product and capacity requirements with us to receive the best Pesticide Bottle Blow Molding Machine Price. Contact us today.

MORE ABOUT YOULI COMPANY

Custom Blow Molding Machines for Global Manufacturers

YOULI is a leading blow molding machine manufacturer in China, committed to integrity, innovation, and excellence. With a strong customer focus, we strive to understand and meet every client’s needs. At YOULI, we deliver high-quality, innovative solutions that drive success.

Strong R&D Capabilities

High Efficiency & Energy Saving

Providing Turnkey Solutions

Excellent After-Sales Support

Our Testimonials

Feedback From Our Clients

Send us a Message

If you have any questions or need assistance, feel free to leave us a message. We respect and protect your privacy.

Most Popular Questions

1. What types of pesticide bottles can your blow molding machines produce?

Our pesticide bottle blow molding machines can produce herbicide bottles, insecticide containers, fertilizer bottles, and chemical jugs from 100ml to 5L+.

2. What materials are suitable for pesticide bottle production?

We recommend HDPE, PP, and multi-layer co-extrusion materials for strong chemical resistance and long-term storage stability.

3. Can you customize bottle shapes and handle designs?

Yes. We offer custom mold development for various shapes, integrated handles, stacking features, and embossed branding.

4. Do your machines support multi-layer extrusion?

Absolutely. For pesticide applications requiring extra barrier layers, we support 3-layer and 6-layer co-extrusion.

5. What is the typical production speed of your machines?

For bottles under 1L, you can expect 1,000–2,500 pcs/hour depending on mold cavities and automation level.

6. Do you offer in-line leak testing and trimming systems?

Yes, we provide automated leak testers, neck cutting, and deflashing units to ensure packaging integrity and clean finish.

7. Are your machines compliant with chemical packaging regulations?

Yes. Our machines produce containers that meet UN/DOT safety and storage standards for agricultural chemicals.

8. Can your machines produce bottles with necks compatible with trigger sprayers?

Yes. We can design molds for trigger sprayer-compatible necks, measuring caps, or safety closures commonly used in agrochemical packaging.

9. What is the lead time for pesticide bottle blow molding machines?

Standard delivery is about 45 working days; custom or turnkey systems may take up to 60 days.

10. Do you offer global support and spare parts?

Yes. As a global pesticide bottle blow molding machine manufacturer, we offer 24/7 remote support, fast spare part shipping, and on-site service if needed.